Double Loop Big Bags are made of polypropylene fabric and are equipped with two load-bearing loops that serve as an extension to the shell of the bag itself.

The top of the 2-loops bulk container resembles the well-known t-shirt bag. Having two separate loops provides more space in the loading area of the bag, making it more comfortable to handle.

At its top point each loop is wrapped and fixed with a cuff made of laminated polypropylene fabric. It protects the loop from damage when contacting hooks and forks of lifting equipment. The bright yellow colour of the sleeves is clearly visible, making it easier for the crane or forklift operator to sling and work.

Containers of this type, as a rule, are manufactured with a safety factor of SF 5:1 and are designed for single use. They can be used to transport almost any type of bulk industrial and food goods weighing from 200 to 1,000 kg.

It is a cost-effective and one of the most popular types of bulk containers. The most common is a two-loops container with a working load of 1 tonne.

White polypropylene fabric with a density of 120 to 160 g/m2 and a tubular width of 120–160 cm is usually used to produce one- and two-loops containers. You can also order fabric containers with other colours and characteristics.

STRUCTURAL ELEMENTS OF BULK CONTAINERS

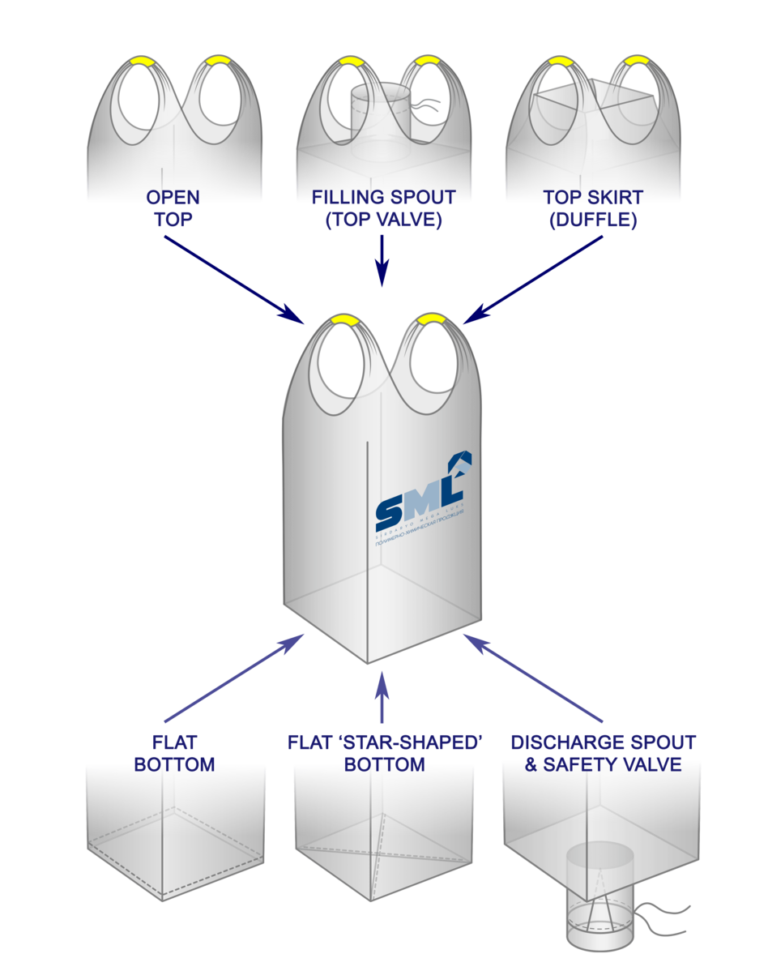

CONTAINER TOP AND LOADING:

- open top

- filling spout (top valve)

- top skirt (duffle)

The filling spout is a hose sewn to the cover of the container made of polypropylene fabric. The valve allows loading products into the container with minimal risk of spillage and pulverisation. At the end of loading the valve hose is folded and tied up with a drawstring.

The top cover in the form of a skirt allows closing the top of the bag after loading by tying the pleat with a drawstring.

CONTAINER BOTTOM AND UNLOADING:

- flat bottom

- flat ‘star-shaped’ bottom (at an angle of 45°)

- discharge spout and safety valve

When unloading Big Bags with a flat bottom, the fabric at the bottom of the container is cut or ripped off with special knives and unloaders.

The version with a discharge spout on the bottom enables controlled unloading and partial unloading of products.

The safety valve protects the discharge spout and its drawstring against damage and snags.

liner insertion

To ensure tightness and maximum safety of the cargo, the bulk container can have a polyethylene liner with a thickness of 60 to 150 microns. Liners are of three types: flat, form-fit (with a neck) and heat-resistant.

CUSTOM PRINTABLE

We can print inscriptions or images on Big Bags using colour flexographic printing (up to 4 colours). The printed image will be contrasting, durable and visible from afar. This is an effective way to increase your brand awareness.

PARAMETERS OF DOUBLE LOOP BULK CONTAINERS

| Permissible workload, kg | 200 to 1,000 |

| Fabric surface density, g/m2 | 120–200 |

| Fabric colour | - white - colour (at the customer's request) - with transparent stripes |

| Fabric structure, thread count per 10 cm2 | 37×37, 37×50 |

| UV stabiliser | Our containers are made of light-stabilised fabric |

| Availability of liners | With and without liners |

| Liner material | Polyethylene |

| Types of polyethylene liners | - conventional - suspended (with a neck) - heat resistant |

| Liner thickness, microns | 60 to 150 |

| Printed logo | Flexographic printing (up to 4 colours) |

| Package | - stacks of 10–25 pcs - pallets of 100–500 pcs |

| Raw materials | Raw materials of the highest grade |

| Standards, certificates and compliance | Products are manufactured conforming to TSh technical specifications. |

| Equipment | Starlinger (Austria): extrusion line and weaving machines Polytek (Turkey): polypropylene fabric cutting line Botheven (Taiwan): flexographic printing machine Union Special (Germany): sewing machines Reifenhauser (Germany): extruder for 3-layer PE film for liners Gunter (Germany): cutting machine for PE liners |

ORDERING TWO-LOOP BIG BAGS

Big Bags can be manufactured to your required dimensions, specifications and design elements.

We are ready to discuss individual terms of collaboration with each customer and provide product samples for testing.

To order containers, you can call by phone or send a request by email:

Republic of Uzbekistan:

+998 90-312-1846

+998 90-799-7900

+998 90-966-6293

sales@sml.uz

cpi@sml.uz

To submit a request for containers from the website, you can fill in the form below or its extended version on the Big Bag Designer page.

After receiving the request, our managers will contact you to answer all your questions, give expert advice and discuss the details of your order.