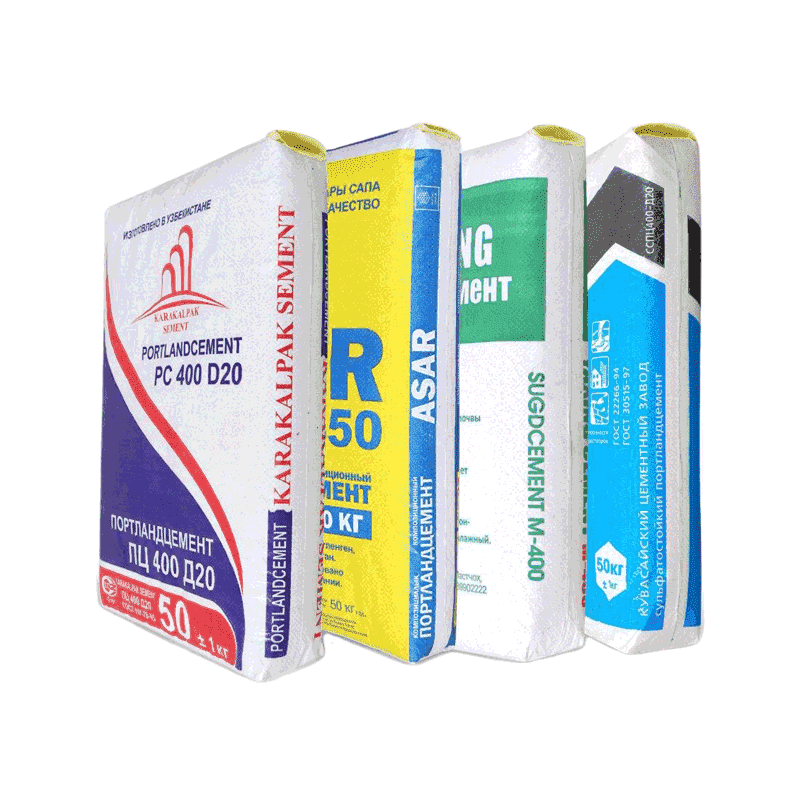

POLYPROPYLENE BAGS

What should the ideal packaging for consumer products look like?

Packaging should protect the contents and be attractive to buyers, but it should also be inexpensive.

Attractive polypropylene fabric bags are becoming increasingly popular in retail.

As for the packaging of consumer goods, the fabric is cached with polypropylene film, the reverse side of which is decorated with photographic images. This ensures effective product advertising and accurate barcode placement.

Dry products weighing more than 10 kg, such as rice, breakfast cereals and animal feed, are safer and cheaper to pack in new PP bags than in traditional paper bags. In addition, polypropylene bags are completely recyclable.

They feature the following benefits:

- lightness and durability built to last

- low material consumption

- production efficiency

- environmental friendliness

- 100% recyclable.

The Company is engaged in the production of a wide range of polymer products of the highest quality meeting the market requirements.

Today SIRDARYO-MEGA-LUKS LLC supplies its products for the light, textile, food and chemical industries and provides Uzbek enterprises with high-quality products.

Polypropylene waven bags are universal containers for the following purposes:

flour bags, bags for cereals, pasta and household sacks.

The polypropylene bag can be used not only for filling, packaging and storing foodstuffs but also for construction materials and various bulk goods.

Polypropylene sacks are superior in performance to linen, jute and paper bags as they are chemically resistant and do not rot.

Polypropylene bags: 25 to 120 kg

Dimensions: 45х75, 45х85, 50х80, 50х85, 50х100, 55х105, 56х115, 58х105, 58х108, 95х130 cm.

Bag weight: 35 to 300 g.

Packing: 500 or 1,000 pcs.

- The bags are designed for filling foodstuffs: sugar, salt, flour, cereals, seeds, pasta, mixed fodder.

- Bags for non-food goods: construction materials, chemicals, fertilisers, claydite and peat as well as bags for small cargoes of transport companies.

- Bags for bulk products: clothing, fabric, cotton wool, rubber products. They are widely used by transport companies for packaging medium-sized goods.

All types of bags can be gravure-printed with logos and images.

We also offer bags with PE liners for bulk food and chemicals.

According to the requirements of our customers, we produce bags with one-sided or double-sided laminated BOPP coating. We also produce polypropylene valve box-type bags of various types and sizes according to the requirements of the customer.

QUALITY OF PRODUCTS

Any kind of bulk goods needs solid and reliable packaging to be transported and delivered to the end customer.

Polypropylene bags are great for any bulk goods since they are much better than paper, linen and jute bags.

Bags made from raw materials are white and are the most durable of the other polypropylene bags.

Polypropylene bags are a convenient, practical and easy-to-use type of packaging. They are designed for filling loose bulk goods for mass consumption and are used as containers in the small wholesale and retail trade of foodstuffs, building materials, various fertilisers etc.

WHAT ARE THE ADVANTAGES OF POLYPROPYLENE BAGS?

- They have high mechanical and impact strength.

- Polypropylene fabric is resistant to repeated bending and abrasion.

- They are highly resistant to boiling water and alkalis.

- Polypropylene bags are resistant to low temperature (up to -70 °C).

- Polypropylene is resistant to high temperature (up to +100 °C).

- Polypropylene bags withstand organic solvents.

- Polypropylene bags are not subject to erosion.

- They do not decompose during long-term storage of highly active substances.

- Polypropylene bags have excellent dielectric properties.

Light weight is another important advantage of polypropylene bags. - Polypropylene bags are environmentally friendly!

All bags are subject to quality control.

Each product is studied in the production and laboratory environments of the enterprise.

Our production workshops carry out the following stages of finished product inspection:

- appearance: visual check for the absence of holes, uneven seams and other mechanical defects

- size check

- weight and density of the bag

- breaking load of the canvas and seams

- the product’s resistance to sunlight

- absence of foreign odours.